Artificial Intelligence (AI) is transforming the retail industry at an unprecedented pace. In fact, according to a study by Marketsplash, the adoption rate of AI in the retail sector is expected to jump from 40% to over 80% within three years to enhance customer experiences and streamline operations. One of the most groundbreaking advancements is the AI-powered “image-to-planogram” technology, revolutionizing retail compliance and efficiency. This innovative planogram generator technology allows retailers to capture an image of a store shelf and automatically generate an editable planogram, ensuring that products are placed correctly and consistently across all locations.

This blog post will explore the concept of “pic to pog,” a term used to describe this transformative technology. We will discuss its benefits, including its advantages for retail compliance, and look ahead to the future of planogram management in retail. Discover how AI-powered image-to-planogram technology sets new standards for operational excellence in the retail sector.

Understanding Planograms and their Impact in Retail

A planogram is a detailed visual representation that depicts the layout of products on retail shelves or displays. It serves as a blueprint for retailers, outlining where and how specific items should be placed to maximize shelf space, attract customer attention, and drive sales. Typically created by visual merchandisers, planograms ensure product placement aligns with marketing strategies and inventory management goals. They consider factors such as product visibility, accessibility, and category adjacency, helping to create a cohesive and efficient shopping experience for customers.

Planograms have a significant impact on both operational efficiency and sales performance. By standardizing product placement across various locations, retailers can maintain consistency in their brand presentation, making it easier for customers to find what they want. This consistency enhances the shopping experience and helps inventory management by ensuring that shelves are stocked according to plan, reducing out-of-stock scenarios, and optimizing product turnover. Well-executed planograms can increase product visibility and impulse purchases, ultimately boosting sales and profitability. In fact, according to Data Semantics, implementing planograms can lead to a 10-20% increase in revenue through optimized product placement and improved customer experience.

Planogram Challenges

Creating effective planograms seems straightforward, right? Just place the products strategically and watch the sales roll in. However, it’s a bit more complicated than that. Creating and maintaining planograms can present several challenges for retailers. One of the primary issues is the time-consuming nature of developing detailed and accurate planograms for each store layout. This process often requires significant manual effort from visual merchandisers, who must account for varying store sizes, inventory levels, and product assortments.

Additionally, ensuring compliance with these planograms across multiple locations can be difficult, requiring constant monitoring and adjustments. Misalignment between the planogram and actual shelf layout can lead to inefficiencies such as out-of-stock items, poor product visibility, and lost sales. The need for frequent updates to accommodate new products, promotions, and seasonal changes further complicates the management of planograms, making it a resource-intensive task for retail operations.

However, the benefits of a well-planned planogram can make or break a retailer’s success. Effective planograms enhance product visibility, optimize shelf space, and improve the shopping experience, increasing sales and customer satisfaction. That’s where finding effective planogram solutions comes in.

Enter AI Planogram Generator Technology

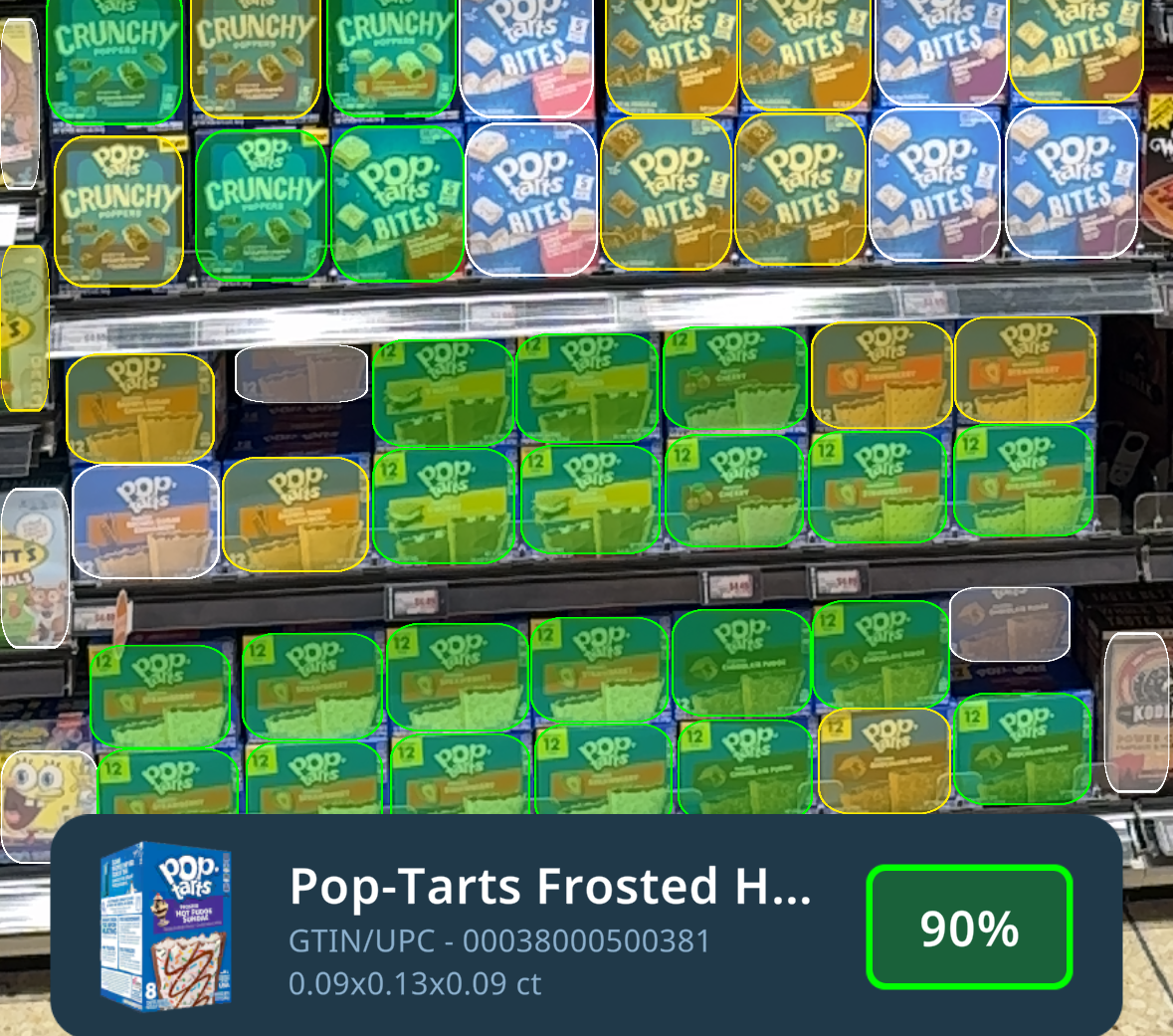

A planogram generator, often called “pic to pog” technology, is an innovative tool that revolutionizes how retailers manage their store layouts. This technology lets users take a picture of a shelf’s current planogram using a smartphone or tablet. The image is then processed by advanced AI software to create an accurate and editable digital planogram within the app or platform.

This digital representation can be easily modified to reflect desired changes in product placement, ensuring that shelves are always stocked according to the most efficient and visually appealing layout. The “pic to pog” technology simplifies the traditionally time-consuming and manual process of planogram creation, providing retailers with a powerful tool to maintain consistency, optimize shelf space, and enhance overall store performance.

Benefits of Planogram Generator Technology

Enhanced Efficiency

Planogram generator technology significantly speeds up the process of creating and updating planograms, reducing the need for manual labor and minimizing errors. For example, in a grocery store, staff can quickly capture an image of a newly stocked cereal aisle and generate an updated planogram within minutes. This eliminates the tedious task of manually plotting each product’s placement and ensures that the layout adheres to the store’s merchandising strategy.

Improved Accuracy

The high precision of planogram generator technology ensures that shelves are stocked correctly according to the plan. For example, the produce section in a grocery store can be meticulously arranged to highlight fresh fruits and vegetables as specified in the planogram. This precision helps maintain the desired aesthetic and organizational structure, enhancing the shopping experience for customers. The National Association for Retail Merchandising Services (NARMS) highlights that “well-designed planograms, when quickly and reliably executed, significantly improve same-store sales”.

Cost Savings

Planogram generator technology leads to significant cost savings by reducing the need for manual labor and minimizing stocking errors. For instance, a supermarket chain can use this technology to optimize shelf space and inventory management in the dairy section. Efficiently arranged shelves reduce product wastage due to spoilage and ensure that popular items are always available, ultimately lowering operational costs and increasing profitability. Efficient use of planogram software can lead to better stock management and reduced out-of-stock incidents, directly impacting sales and operational efficiency.

The Role of AI in Planogram Compliance

No matter how meticulously planograms are designed, their effectiveness hinges entirely on accurate and consistent implementation across all retail locations. Ensuring planogram compliance is a critical aspect of retail strategy, as it directly influences product availability, brand consistency, and sales performance. Compliance with planograms means that products are placed precisely as intended, which is essential for optimizing shelf space and maximizing sales. With strict adherence to planograms, retailers can avoid inconsistencies that can lead to poor product visibility, out-of-stock situations, and, ultimately, lost revenue.

With technological advancements, achieving planogram compliance has become easier and more efficient. Modern tools and technologies streamline the process, making it simpler for retailers to maintain consistent and accurate product placement across all locations.

Planogram generators work because of AI. AI-driven image detection involves training neural networks on large datasets to accurately identify and locate objects within images. The products are identified and matched against a product database to retrieve detailed information such as SKU, size, and category. This information, combined with the precise placement of the products, is used to build out the planogram. AI-driven insights and automation enable retailers to detect and rectify any deviations from the planogram quickly. By leveraging AI, retailers can achieve higher levels of accuracy, efficiency, and compliance in their merchandising strategies, ensuring optimal performance and customer satisfaction.

Next Level Planogram Generation at InContext

InContext’s augmented reality (AR) field enablement retail execution app, SMX GO, leverages “pic to pog” cutting edge object detection technology to significantly enhance its platform, providing retailers with powerful planogram validation and optimization tools. This innovative technology revolutionizes the planogram validation process by allowing users to create overlays of how an AR planogram on the physical shelf s appear in-store. Retailers merchandising associates can quickly visualize and validate planograms on-site, communicate discrepancies back to HQ, and even generate a planogram from a picture enabling seamless collaboration and sharing points of interruption directly within the store environment. This capability streamlines the sell-in process, helping retailers capture more floor space quickly and efficiently, ultimately driving sales and improving overall store performance POG reset and maintenance process by providing merchandisers with a user-friendly tool, and HQ with the knowledge of when a POG was set, if it was set to spec, and allow for quick adjustments.

Our AI software plays a pivotal role in enhancing planogram compliance performance by providing AI-driven insights at the shelf and enabling automation and real-time adjustments. For example, InContext’s Optimization AI engine can recommend what SKU to put in place of an out of stock. That’s because InContext has a shopper behavior data lake of over 2 million shopping missions that is predictive greater than 85%. Planograms become self-healing as a result. AI systems can analyze vast amounts of planogram data to generate actionable insights that improve compliance and optimize shelf management. For example, it can identify patterns in customer purchasing behavior and suggest the most effective product placements to boost sales. It can also detect discrepancies between the planned and actual shelf layouts, recommending specific adjustments to ensure that each store adheres to the prescribed planogram.

Our image recognition first-time-right planogram execution can be used in any location, at any time. Automated alerts can be generated when a deviation from the planogram is detected, prompting immediate corrective actions by the merchandising teams. This ensures that any issues are addressed swiftly, maintaining the integrity of the planogram. Additionally, the Optimization AI software allows retailers to continuously monitor and refine their shelf layouts. For instance, if a popular product frequently runs out of stock, Optimization AI can suggest reconfiguring the planogram to allocate more space to that item while balancing the shelving principle variables that drive category growth, thereby improving inventory management and customer satisfaction.

Looking ahead, we plan to roll out enhanced compliance features in SMX GO this fall, further expanding the app’s capabilities. These new features will offer real-time compliance checks and automated alerts, ensuring in-store planograms match the intended layouts. By leveraging advanced AI systems, we help retailers to achieve planogram compliance and predict customer behavior with some of the highest correlation rates. Retail Merchandising is the next frontier of Retail growth. InContext’s advanced retail merchandising technology suite can reduce store operations costs and drive growth without impact to your existing tech stack.

Partner With Us to Transform Your Retail Store

“Pic to pog” technology offers numerous benefits and applications that can transform retail operations. By enhancing efficiency, improving accuracy, enabling real-time compliance, and reducing costs, this AI-driven solution is a game-changer for planogram management. With competition rising, adopting advanced technologies is crucial for retailers looking to stay competitive. The ability to quickly generate, adjust, and maintain planograms ensures that shelves are always optimally stocked and presented, leading to increased sales and customer satisfaction.

Embracing AI-driven solutions like “pic to pog” through platforms such as SMX GO is not just an option but a necessity for modern retailers. These technologies streamline processes, provide valuable insights, and allow for dynamic adjustments that keep stores running smoothly. If you’re ready to take your business to the next level, partner with InContext. Adopting “pic to pog” technology can enhance operations, maintain compliance, and achieve greater efficiency. This ensures your stores are always ready to meet customer expectations and drive business success.